PREMIUM FULL BIAX CARBON TECHNOLOGY

Click ![]() for detailed technology information or check out Dany's tech-talk video.

for detailed technology information or check out Dany's tech-talk video.

Next-level windsurfing board technology

Our Premium Responsive Carbon Construction (PRCC) is the result of many years of experience and hard work, dedicated to finding the perfect combination of light weight, flex and durability. It is used exclusively in all our boards.

While our competitors offer a wide range of constructions on different quality levels, our goal has been to solely develop and build the best windsurfing boards possible, to enjoy for many years.

At Bruch Boards we only use the most exclusive materials, taking our Responsive Carbon Technology to a quality level unmatched on the windsurfing market.

Pigments in the Resin and Ceramic Gel Code for the Rails

In the final lamination process we use color pigments to put into our resin, this way we hardly use paint sprayed onto our boards. To be exact, we use only 60 grams of paint for the whole board. Like that we reduce the weight and avoid paint chipping off when touching sharp objects, to maintain a great look for a long time.

The final touch are the rails: We add a ceramic gel code to harden up the first layer, which is the most exposed to scratches, when putting down your board coming off the water.

We want your board to maintain a shiny look for many many years!

Premium Bruch pads & footstraps

High quality straps with double velcro for adjustments and a stiff strong belt inside to maintain a well shaped, round strap on the board.

This will allow you to always keep the feeling of control trough your feet.

The board will react immediately once you initiate any type of pressure onto it, either for your bottom turn, top turn or gybe.

Soft neoprene around the stiff belt and no hard edges, a joy for your feet that you will always appreciate.

Once in the strap, the combination of 5mm sponch for softness and 6mm “HPE” pad will surprise you in therms of grip and comfortableness.

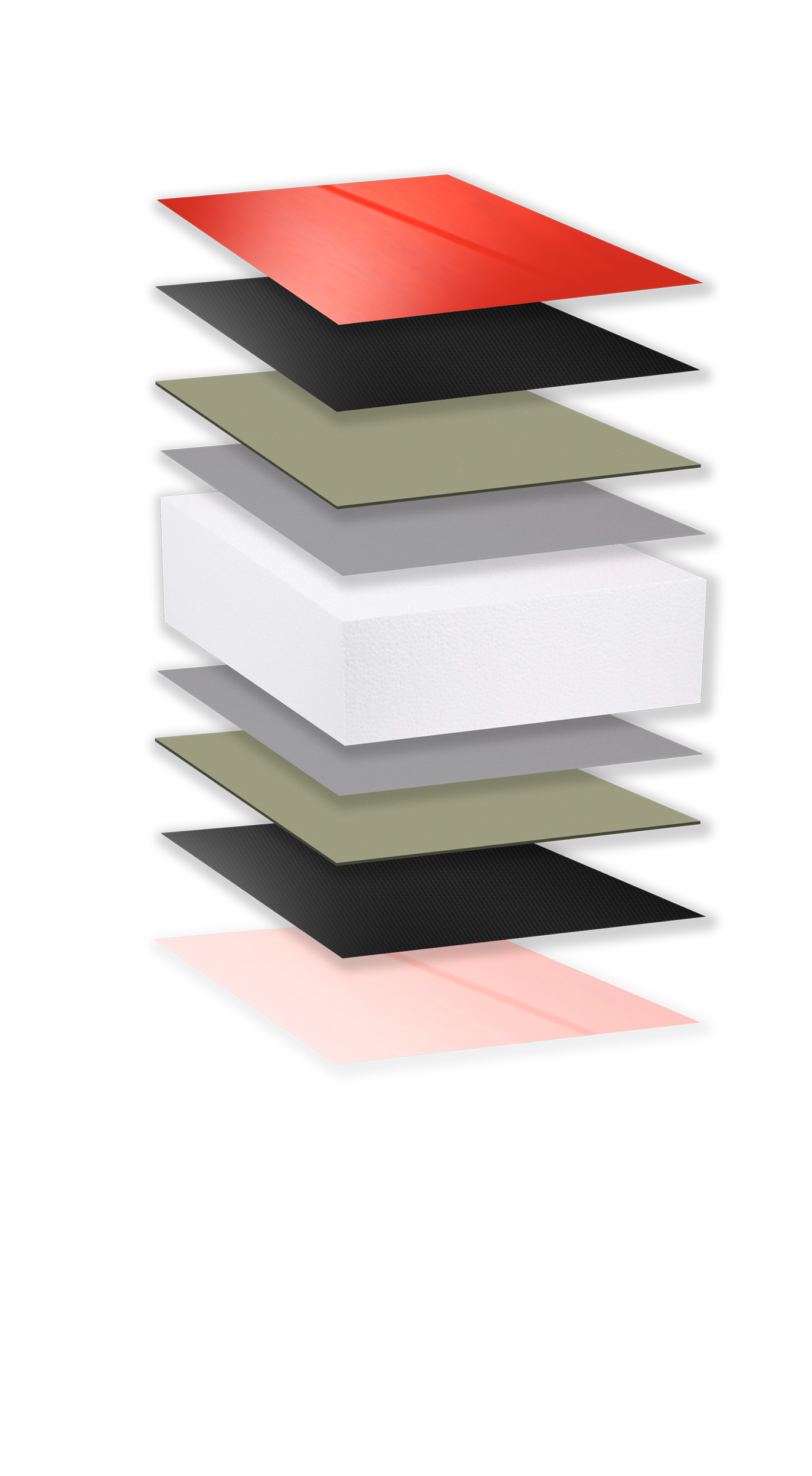

Deck & bottom 100% Biax Carbon 45º

We only offer 1 technology, because it is the best in performance, durability, flex and to maintain the “alive” feeling of the board. The “Responsive Carbon Construction”.

The “Responsive Carbon Construction”, is a full “Biax Carbon 45º” lamination of the deck and bottom of the board.

45º means, that the webbing of the carbon fibers, on the carbon matt, have a 45º angle when they are webbed together.

Applying this onto the board in a unidirectional way during the lamination process, thanks to this 45º angle, you will reduce stiffness and will allow the board to have a certain amount of flex, which is important when landing a jump or initiating a bottom turn or jibe.

All we want is a smooth ride!

Biax Carbon Reinforcements

We don’t safe in materials, it's more, we have some extra layers, all in Biax Carbon 45º, to reinforce the parts that suffer the most, to give durability and an extended life to our boards.

The first reinforcement layers go to the traditional parts: the area under your feet, from rail to rail across the whole length (to give the whole board more strength). Then the mast track, nose and tail will have their patches as most boards use to have.

We add another full layer of Biax Carbon 45º, all the way from the tail, until the front of the mast track area, protecting the board up to the part where we step while tacking. That way nothing can get soft, no matter how many times you step on all standing or walking areas of your board.

On the bottom, the fin boxes will have a full layer, from tail to the upper part of the boxes. The extra magic: To avoid the typical damage in the jumping and landing areas, that usually get more pronounced or where boards even bend, after a longer time of usage, specially when jumping a lot, we add another full layer of Biax Carbon 45º, from tail to all the way up to the center of the board.

Breakage is not allowed in our philosophy!

The Sandwich Method

The sandwich method is nothing new in windsurfing board construction.

There are several different types, densities and brands/suppliers of the Airex or PVC sheets used to create a more resistant shell, protecting the shape of the EPS.

The big difference is the thickness used of those Airex/PVC sheets: We find that the perfect compromise of durability and weight is 5mm for the bottom of the board and 3mm for the deck.

Heavy duty inserts, fin boxes and mast track

All our inserts, like fin boxes and the mast track, are put into an extra Airex/PVC block, so that these parts can never cause you an issue, no matter how long you have used your board.

Hard landings, or heavy hits on the rocks, will be taken just like that.

The EPS

The EPS core of each board is CNC-shaped and finished by hand, where the shaper uses precise templates to verify each step, guaranteeing the 100% accuracy of the shape.

Glass and Unidirectional Carbon

The EPS will get reinforced, before the “sandwich” goes on, with another layer of carbon on the deck. This time it's another high tech material that does not create any conflicts with the flex of the Biax Carbon 45º, the Unidirectional Carbon, a carbon that has full flex in direction of the length of the board, but full strength in the direction across the board, from rail to rail.

Thanks to this material, the core or heart of our boards stays intact, no matter how long you use it.

A thin layer of glass always has to be added to any carbon. Carbon fibres, after a long time of usage, start to splinter and break, but thanks to the glass layer, this just can’t happen.

Once again, this will extend the life of your board considerably.